Attention! If necessary (puncture, air leakage due to deformation of the wheel rim) tubeless tire can be assembled with a tube.

A quick repair of a tubeless tire can be made using a special repair kit that provides reliable sealing of the damaged area. However, it should be borne in mind that such repairs are only suitable for repairing small punctures. In most cases, this is a temporary measure in order to be able to get to the place of repair or parking. Tire repair kits may differ in the material included. Therefore, when performing work, you must follow the instructions that come with the kit.

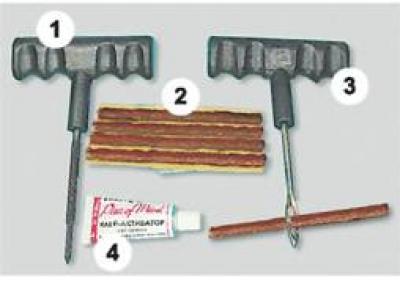

1 - a device with a threaded tip or notches; 2 - strips of raw rubber; 3 - needle with split eye; 4 - adhesive activator for raw rubber

Warning! A tire with a large puncture, cord damage or sidewall cut must be replaced.

Tire repair is possible without removing the wheel, it is enough to jack up the car and place it on a support. Vehicle operation is allowed immediately after repair.

Warning! When driving on a repaired tire, care should be taken: reduce the speed of movement so that in case of sudden tire failure, you can take adequate measures; try to go around bumps in the road, or drive them at low speed. A repaired tire should be replaced as soon as possible. It is permissible to use such a tire on a spare wheel.

Execution sequence

1. Find the puncture site (by air escaping from a puncture or by an object that has punctured a tire).

2. Install the wheel so that the puncture site is accessible for repairs.

3. Remove the object that pierced the tire.

4. Inflate the wheel to a pressure of 2.0 bar (0.2 MPa).

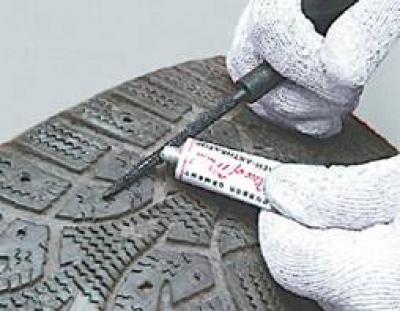

5. We apply a few drops of glue to the tip of the device with a notch.

6. Having inserted the tip of the device into the puncture hole, we push it in and out several times.

7. Insert a strip of raw rubber into a needle with a split eye, so that the needle divides the strip in half.

8. Apply activator glue to the rubber strip.

9. Using a needle, we insert a strip of raw rubber into the puncture hole so that about half of the strip protrudes from each side.

10. Carefully remove the needle so that the rubber strip remains in the hole.

11. Cut off the protruding parts of the repair strip flush with the surface of the tire.

12. We bring the air pressure in the tire to normal (see "Tires - pressure check").