It was installed on the VAZ-21011 until 1980, and on the VAZ-2101 and VAZ-2102 since 1980, a foot-operated windshield washer was installed. This pump has an additional wiper switch 5. When you press the button, fluid starts to splash, and then the wiper turns on.

Since 1980, on the VAZ-21013 and VAZ-21011, instead of a foot-operated windshield washer, an electric pump has been used, installed directly on the lid of the windshield washer fluid reservoir.

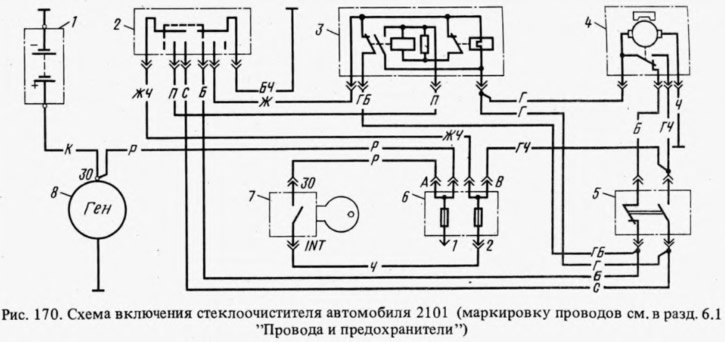

With the constant operation of the wiper, the current comes from the output "+" battery 1 or clamp "30" generator 8 through the armature winding of the electric motor 4, bypassing the wiper relay 3. The electric motor runs at a constant speed, and the wiper blades swing at a frequency of 50-60 cycles per minute.

In the case of switching the wiper to intermittent operation, the current comes from the clamp "30" generator through fuse box 6 to switch 2 and from it along the red wire to relay 3. Then along the yellow wire from relay 3 to switch 2 and along the white-black wire to "mass".

In a relay, current flows through the coil of an electromagnet and causes the relay to operate. Upper relay contacts (on the left side of the diagram) open, and the lower contacts (on the right) close. The current flowing through the lower contacts of the relay goes through the blue wire to the electric motor and the latter starts to rotate.

When the relay is activated, the current also flows through the breaker winding (the diagram is shown on the right), which heats up. The bimetallic plate of the breaker bends from heating and opens the breaker contacts, turning off the power to the relay electromagnet winding. The lower contacts of the relay open, the current to the motor 4 is interrupted, and it stops.

Since the current no longer flows through the relay breaker winding, it cools down along with the bimetallic plate. The plate takes its former shape and the breaker contacts are closed, turning on the power supply of the relay electromagnet winding. The described cycle is repeated again with a frequency of 9-17 times per minute.

During one cycle, the brush completes one double stroke and stops in the down position. At the initial moment of turning on the wiper for intermittent operation, while the bimetallic breaker plate has not yet heated up, the brushes can make up to four continuous strokes.

The wiper is turned off after the key or switch lever 2 is returned to its original position. In this case, the current to the armature winding of the electric motor is supplied through a blue wire with a black stripe from the plug "IN" fuse box through the contacts of the limit switch of the electric motor. At the moment when the wiper blades come to the lower position, the protrusion of the cam of the worm gear of the gearbox will open the contacts of the limit switch and turn off the power to the armature winding. The motor armature will stop and the wiper blades will remain in the down position.

Since 1985, a reusable thermobimetallic fuse has been installed in windshield wipers. Its purpose is to protect the electric motor from overloads, for example, when brushes freeze to glass, etc.